Kovai hammers engineered

for driller needs

Delivering speed, reliability and

cost - effectiveness

About Us

S. Krishnaswamy

Founder

“We at Kovai, passionately innovate and engineer solutions for most critical and challenging problems in the Industry. We strive for introducing world class products that performs significantly better than what is available in the market.”

Kovai Drilling Applications was established three decades ago by Mr. Krishnaswamy, a visionary entrepreneur and pioneer in CNC Machining. Operating from multiple state-of-the-art factory locations, we specialize in manufacturing complex, high-precision components for diverse sectors, including automotive, aerospace, energy, mining, and textiles.

His unwavering passion for innovation and commitment to quality set the benchmark for our ongoing operations. While he may no longer be with us, his spirit continues to inspire every project we embark upon and every component we manufacture. His legacy serves as a timeless source of motivation for our team, propelling us to strive for excellence in all aspects of our work.

Precision and innovation

Transforming the landscape of hard rock drilling

At our core, we aspire to be pioneers in the drilling industry, driving innovation that transforms the way drilling is accomplished. Our vision is to combine cutting-edge technology with a deep understanding of the needs of drillers to create a new era of drilling efficiency and effectiveness. Our ultimate goal is to empower drillers with the tools they need to achieve unprecedented levels of drilling speed, efficiency, and satisfaction in their work, setting a new standard for excellence in drilling.

Key features

- Fastest drilling in harsh terrains powered by longer stroke length.

- Enhanced durability with hardened components through special heat treatment process.

- Easily serviceable due to simplistic design involving less number of parts.

- Lasts longer as a result of reversible, groove-free barrel design with thick walls.

- Adapts to diverse drilling needs of various terrains and compressor models.

- Low energy consumption while delivering high performance consistently through entire life.

Products

Precision redefined for your success

We offer a diverse selection of DTH hammers and drill bits in various sizes to meet the wide-ranging needs of our customers

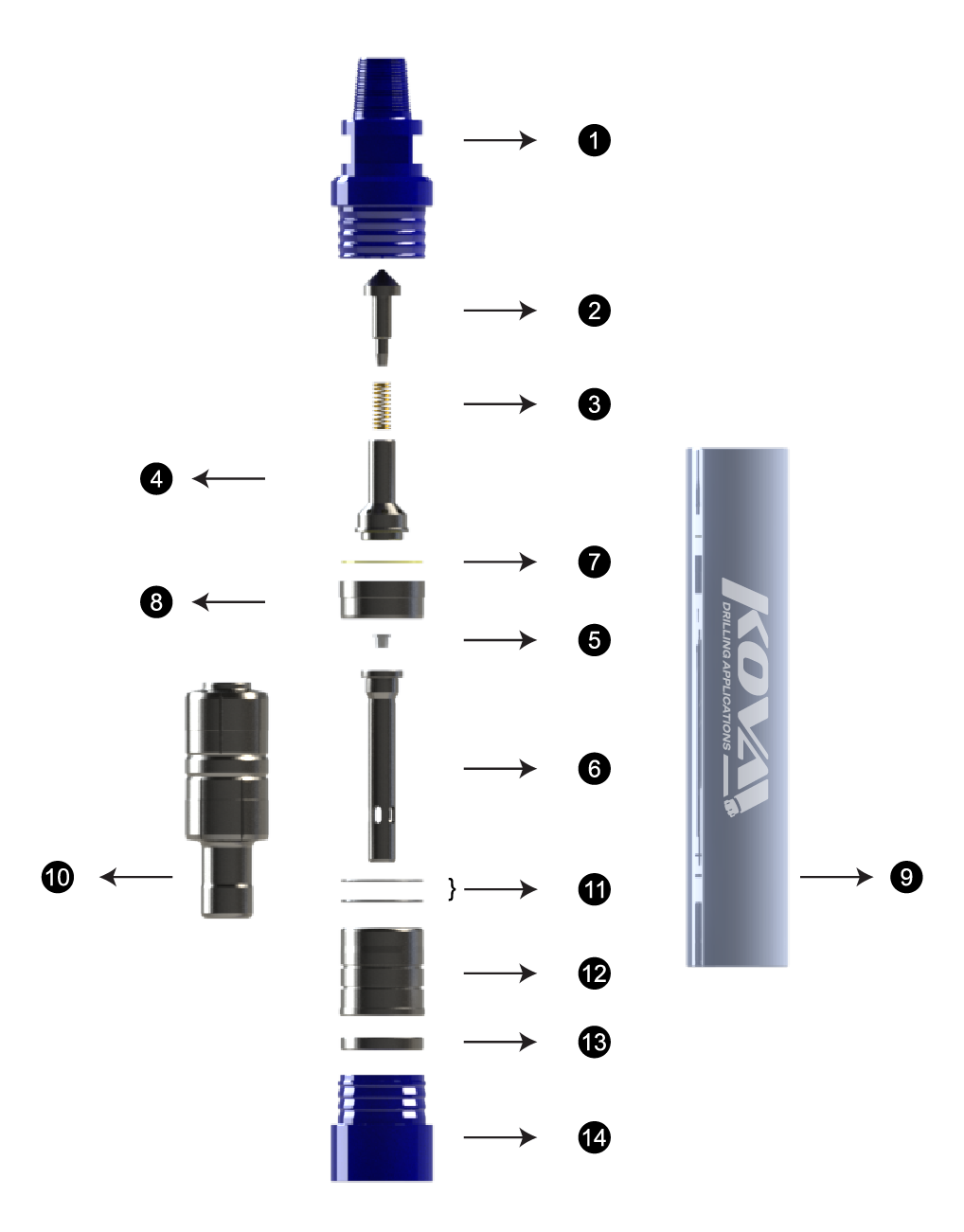

Kovai 650W DTH hammer

| Part list | ||

|---|---|---|

| Item | Part number | Description |

| 1 | KH 6501 | Back Head (Top Sub) 3 1/2″ Regular Pin |

| 2 | KH 6502 | Check Valve |

| 3 | KH 6503 | Check Valve Spring |

| 4 | KH 6504 | Air Distributor |

| 5 | KH 6505 | Ships With Choke – Blank, 1/8″, 3/16″ |

| 6 | KH 6506 | Control Tube |

| 7 | KH 6507 | Nylon Spacer |

| 8 | KH 6508 | Control Tube Head |

| 9 | KH 6509 | Barrel |

| 10 | KH 6510 | Piston |

| 11 | KH 6511 | O-Ring |

| 12 | KH 6512 | Guide Bush |

| 13 | KH 6513 | Bit Lock |

| 14 | KH 6514 | Drive Sub suitable for M60 & QL60 Shank |

| Operating parameters | |

|---|---|

| Air pressure | Air consumption |

| 20.7 Bar [300 PSI] 22.8 Bar [330 PSI] 25.2 Bar [365 PSI] |

29.7 m3/min [1050 SCFM] 31.2 m3/min [1100 SCFM] 36.8 m3/min [1300 SCFM] |

| Oil consumption at 25.2 Bar (365 PSI) : 0.9 l/hr [0.25 gallon/hr] | |

| Recommended rotation speed : 15 r/min to 60 r/min | |

| Minimum diameter difference between barrel land bit : 12 mm [0.471] | |

| Technical specifications | |

|---|---|

| Recommended bit diameter. mm [in] | 165 – 200 mm [6.5″ – 8.0″] |

| Barrel outside diameter, mm [in] | 148.0 [5.8] |

| Barrel discard diameter mm [in] | 136 [5.8″] |

| Wrench flat size on Back Head mm [in] | 90 [3.54″] |

| Length without drill bit. mm [in] | 1048 [41.25] |

| Weight without drill bit, kg [ibs] | 90 [198.4] |

Key Differentiation

Enhanced performance

Optimized airflow design and longer stroke length of Piston for exceptional speed during hard rock drilling.

Extended lifespan

Advanced heat treatment methods for part durability, a thicker control guide tube to prevent breakage and a groove-free, thicker main barrel that is reversible, ensuring a longer product life.

Consistent performance

Adapts to diverse drilling needs of various terrains and compressor models, with air consumption and performance maintained at peak levels throughout the hammer's lifespan

Reliability

With fewer components and reduced failures, our hammers offer trouble-free operation and a lower frequency of part replacement, ensuring dependable performance.

Cost efficiency

Benefit from a lower cost of ownership due to low energy consumption and longer life of our top-tier drilling solution.

Serviceability

Simplified product build with only 14 items, significantly less number of parts than other hammer brands, making it easy to maintain and assemble

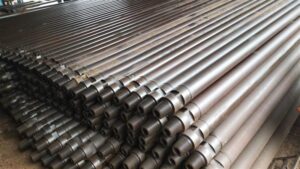

DTH Drill Rods

Kovai Drilling Applications offers high-strength DTH Drill Rods engineered for superior performance in demanding drilling environments. Manufactured from premium-grade alloy steel and heat-treated for enhanced durability, our rods ensure optimal energy transfer, minimal wear, and extended service life. With precision-threaded connections and consistent quality control, our drill rods are built to withstand extreme operational loads, making them ideal for water well, mining and geotechnical applications.

DTH Drill Bits

Kovai Drilling Applications supplies high-quality DTH drill bits designed for performance and durability in demanding conditions. Available in concave, convex, and flat face designs with QL and Mission shanks, our bits ensure excellent energy transfer, fast penetration, and long service life. Made from alloy steel with tungsten carbide buttons, they are ideal for water well, mining, and geotechnical drilling

Our experience

Over 15 years of research and development

Thousands of successful drilling sites

More than a hundred satisfied customers

Contact Information

We look forward to connecting with you and discussing how our expertise can benefit your projects.

Office address

-

2699 Interlude Street,

San Jose, CA - 95122

Warehouse address

-

340 Port Road 22,

Stockton, CA - 95203

Get in touch

Office address

-

2699 Interlude Street,

San Jose, CA - 95122

Warehouse address

-

340 Port Road 22,

Stockton, CA - 95203